Lockheed Martin’s F-35 Lightning II stands as one of the most advanced fighter jets globally. Business Insider recently toured a facility where this stealth jet is manufactured.

The production line located in Fort Worth, Texas, is churning out more than 150 aircraft each year. Set within a massive factory in Texas, thousands of employees work tirelessly around the clock to assemble the US military’s most sophisticated multi-role fighter jet: the F-35 Lightning II Joint Strike Fighter. This facility, operated by the defense leader Lockheed Martin, spans over a mile and produces over 150 jets annually. The scale is immense, with employees using golf carts or bicycles to navigate the expansive space.

During the tour of the factory, officially named Air Force Plant 4, the vastness of the production line was unmistakable. An overhead view showcases F-35s transitioning from bare metal components — often unrecognizable to those not familiar — to nearly completed jets: single-engine, supersonic stealth fighters designed to excel in various combat scenarios.

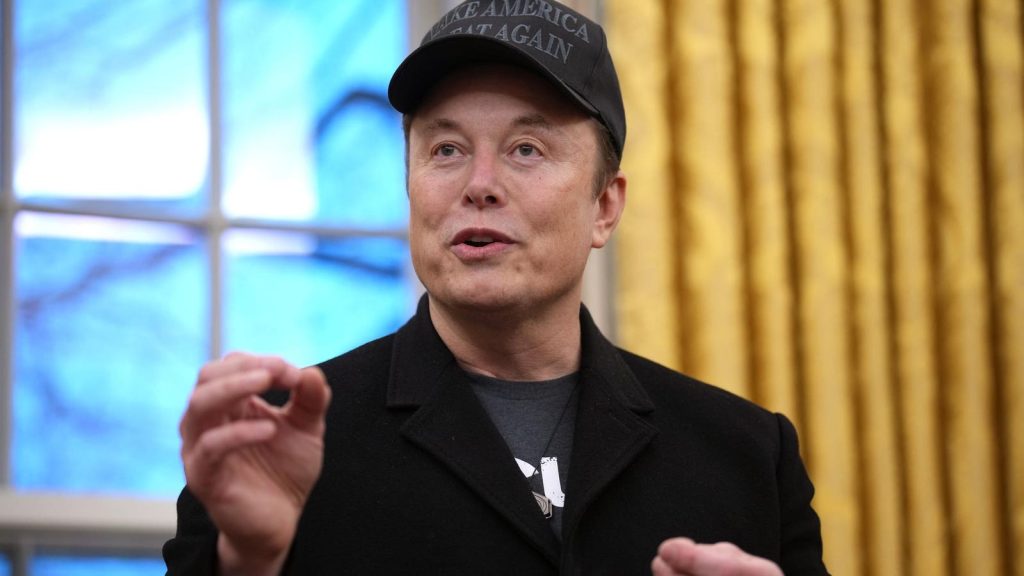

The F-35 is recognized as the world’s most expensive weapon program, anticipated to exceed a lifetime cost of $2 trillion. Prominent figures like Elon Musk have openly criticized the aircraft due to escalating program costs, sustainability issues, and developmental hurdles. Nevertheless, the F-35 continues to receive upgrades and maintains its reputation as a leading fifth-generation fighter.

Lockheed claims that the jet’s production contributes approximately $72 billion annually to the US economy, supported by a network of suppliers and hundreds of thousands of workers across the nation.

The construction of a new F-35 takes roughly a year and a half. Air Force Plant 4 has been producing warplanes for several decades, starting with bombers during World War II, moving on to the now-retired F-111 Aardvark in the 1960s, and later, the F-16 fighter jets.

Another perspective highlighting the F-35 production line.

Parts for the F-35, of which there are thousands, are sourced from around the globe due to the multinational nature of the jet’s project. One of the significant challenges faced in building the fighter, as noted by BI, is ensuring a consistent supply of parts delivered to the Fort Worth production facility.

Once the fighters reach the end of the assembly line, they are prepared to be painted in their distinctive gray color. According to the company, the paint is engineered to absorb and reduce radar signals, enhancing the aircraft’s stealth capabilities. The painting takes place in a designated building equipped with hangars that can be sealed off during the coloring process. While some automation is utilized in the construction of an F-35 — particularly in assembling the wing structure and during the painting phase — skilled labor remains essential.